Driven by Excellence

System Interface Components

System Interface Components

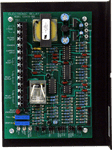

System interface components expand the capabilities of DC and AC drives by adding an external means to interface with other equipment or provide additional control features not supplied as standard by the drive. Carotron has the most extensive group of system interface components in the industry. Each item developed by Carotron offers engineered solutions to real world problems and applications. Along with the Carotron manufactured items we sell encoders, load cells, and air processing equipment that work well with our manufactured products.System Interface Component Solutions and Applications

System Interface Components can be grouped into categories based on their typical use. Here is a list of applications to help understand the wide variety of System Interface Components offered by Carotron.Reference Control

These items allow for accel/decel control, signal scaling, signal isolation or signal buffering of voltage signals, milliamp signals, encoder signals, or frequency signals for use as a speed or torque reference to a DC or AC drive. Carotron also offers a master reference controller that can generate four reference outputs to use with four individual drives. Electronic replacements for a Motor Operated Potentiometer (MOP) are also offered to allow a speed reference to be controlled by pushbuttons for increase and decrease functions.

- C11698-000 Accel / Decel & Power Supply

- ADM290-000 Accel / Decel Module

- Signal Follower Card C10032-00

- Signal Isolation Card C10209-00

- Signal Isolation Module SIM200-000

- Precision Bipolar Isolation Card D10562-000

- Electronic MOP Card D10341-000

- Electronic MOP Module MOP250-000

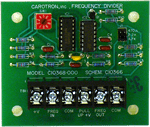

- Frequency Divider Card C10368-000

- Frequency Isolation Module FIM100-000

- Frequency to Voltage Converter Card C10330-000

- Precision Frequency to Voltage Converter Card C11451-000

- Frequency to Voltage Module FTV220-000

- Voltage to Frequency Module VTF230-000

- Multiplier and Divider Card D11005-000

- Multiplier Module MUL270-000

- Divider Module DIV280-000

- MicroManager 3000-CRG Center Reference Generator

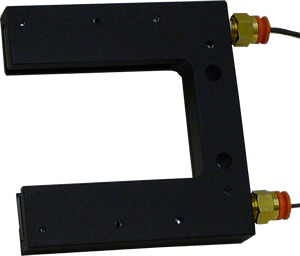

Dancer Position Sensors

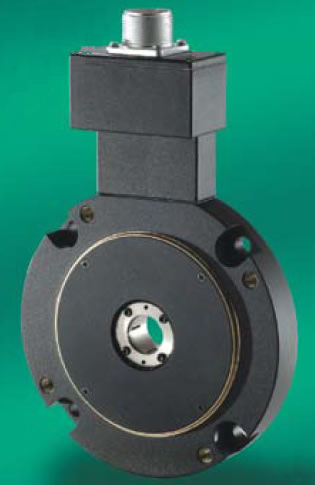

Items in this category are for generating a dancer position signal based on a machine mounted mechanical dancer that is moved by the web being processed. The Carotron Dancer Sensors when mechanically coupled to the dancer provide a signal proportional to dancer position. The position signals can be produced with a dancer duty potentiometer or analog proximity sensor that senses the rotation of a calibrated cam. Carotron also offers a teachable multi-turn sensor that simplifies mechanical gearing requirements for full signal output. For loop sensing with no mechanical dancer or measuring dancer position without mechanical coupling, Carotron offers the Sonictrac and Sonictrac Pro sonar units.

- Dancer Duty Potentiometer DDP01-K0XX & DDP02-K0XX

- Non-Contact Dancer Sensor NCD01-000 & NCD02-000

- Washdown Duty Non-Contact Dancer Sensor WDDC1-XXX,WDDC2-XXX,WDDV1-XXX & WDDV2-XXX

- Teachable Multi-Turn Position Sensor MTPS-16-010

- Sonitrac Measuring Unit SMU100-XXX

- Sonictrac Pro STP200-000

Dancer Position Controllers

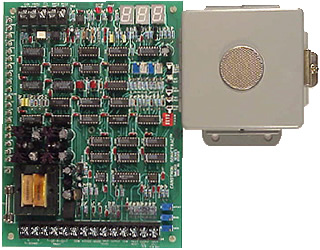

A control loop can be produced external to an AC or DC Drive to regulate motor speed by controlling the position of a machine mounted mechanical dancer. The Carotron Dancer Position Controllers offer a superior PI or PID loop design for these applications. Both analog and microprocessor-based controllers are provided.

- P.I.D Dancer Position Card D10541-000

- Proportional Integral Loop Module PI240-000

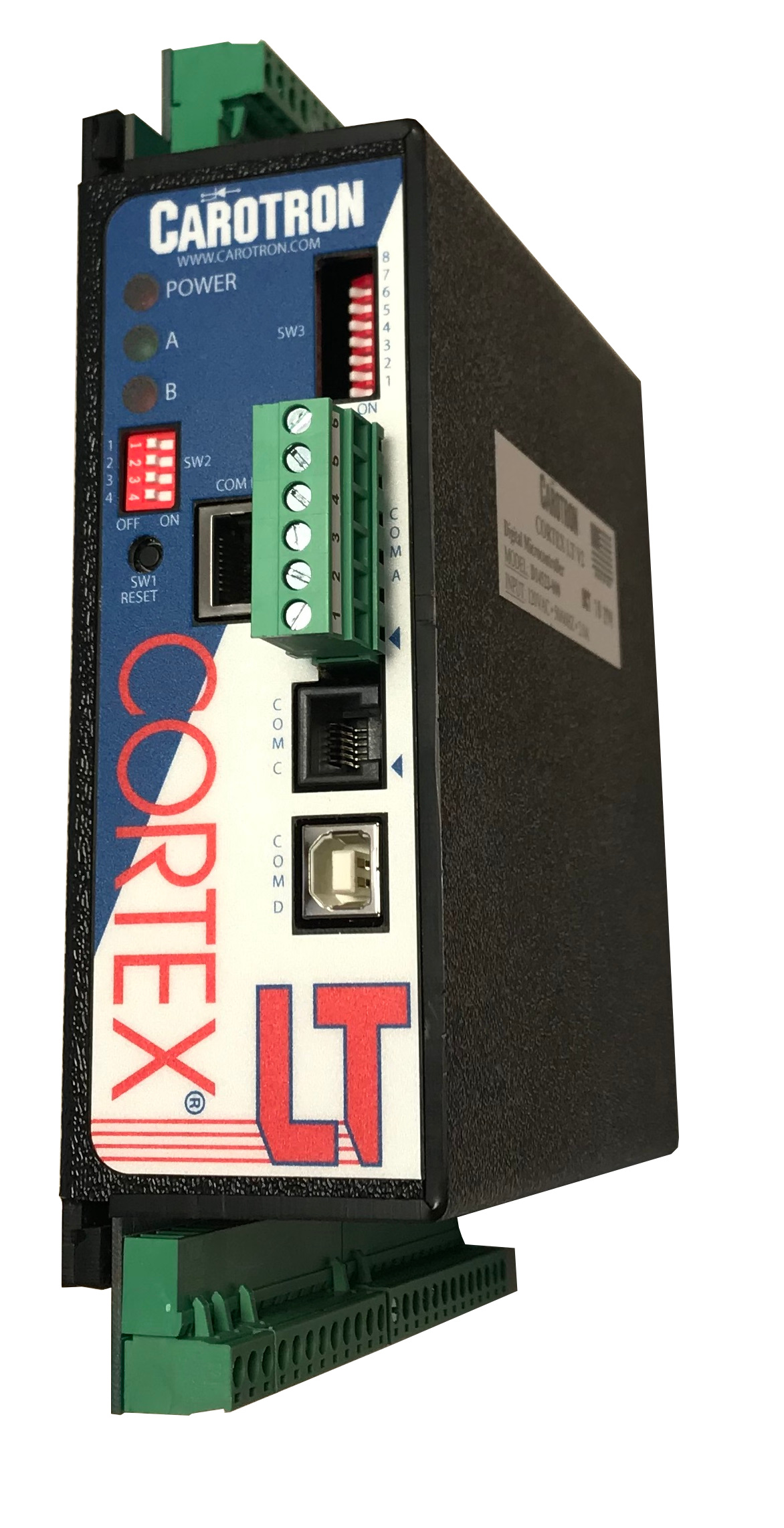

- Cortex LT System Controller (Programmable)

Constant Tension Center Wind (CTCW)

For constant tension of a center winding roll, the torque applied for web tension must increase directly as the roll diameter increases. CTCW controllers therefore calculate the roll diameter to vary the output torque reference signal to be sent to a DC or AC Drive operating in torque mode in order to regulate the winder roll tension. Depending on the material being wound, it is usually desirable to produce a tapering tension as the roll builds to prevent telescoping or crushing the winder core. CTCW controllers have the ability to generate this tapering function to accommodate a wide range of materials and winding conditions. Since the DC or AC drive is operated in torque mode, it is also necessary for the CTCW controller to produce additional signals to compensate for torque losses from acceleration and from system friction. Carotron offers all of these functions in our analog and microprocessor based CTCW controllers.

- Constant Tension Centerwind Controller D10337-000

- MicroManager 3000-CTCW Constant Tension Centerwind Controller (Programmable)

- Cortex LT System Controller (Programmable)

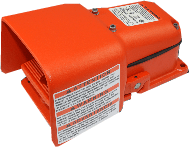

Electronic Relay Functions

In systems it is often required to have a relay control to let you know when a machine speed is reached so that other equipment can be turned on or off. The C10472-000 unit is the most versatile since it can handle AC or DC voltage up to 250V and milliamp DC signals up to 50mADC. The ERM260-000 is a compact Din-rail mount unit, but it can only handle 0-10 VDC or 0-20 mADC as control inputs. The C10334-000 Zero Speed Relay Card is specifically designed to sense motor armature voltage to indicate a safe shut down for armature contactors or safe contactor reversing. Carotron also offers a Programmable Logic Relay from TECO.

- Electronic Relay Card C10472-000

- Electronic Relay Module ERM260-000